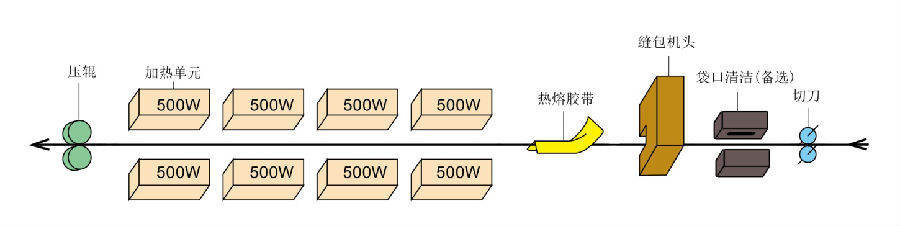

Heat-sealing and stitching workflow: cutter: trimming the mouth of the bag → cleaning the mouth of the bag (optional) → sewing machine: sewing of the outer bag → hot-melt tape → heat sealing of the inner bag (heated by 4 groups of heating blocks) → pressing roller pressing

Product Description:

Serial number | model Specification | GKS-14D |

1 | Sealing speed (m/min) | 7~10 |

2 | Heating block power (Kw) | 0.5×8 |

3 | Sealing machine power (Kw) | 0.4 |

4 | Sewing machine power (Kw) | 0.4 |

5 | Cleaning power of bag mouth (Kw) | 0.55 (optional) |

6 | Total power (Kw) | 5.5 |

7 | Equipment size [length×width×height (mm)] | 2850×1090×2052 |

8 | Weight (Kg) | Approximately 580 |

9 | Suture head | GS-7C |

10 | Sealing height (mm) | 800~1700 (from the ground) |

11 | Sealing temperature | 0~400℃ |

12 | Scope of application | 4-layer flat paper bag, heat-sealed with PE film in the bag, and hot-melt tape on the outside |

The company has many years of experience in industrial robot system integration, combined with internationally renowned brand industrial robots in welding, handling,Robot palletizing palletizingSystem integration cases in other industries have won unanimous praise from users. And has a complete technical center, processing base, after-sales service center, which provides a solid guarantee for users' services. Welcome new and old customers to inquire!