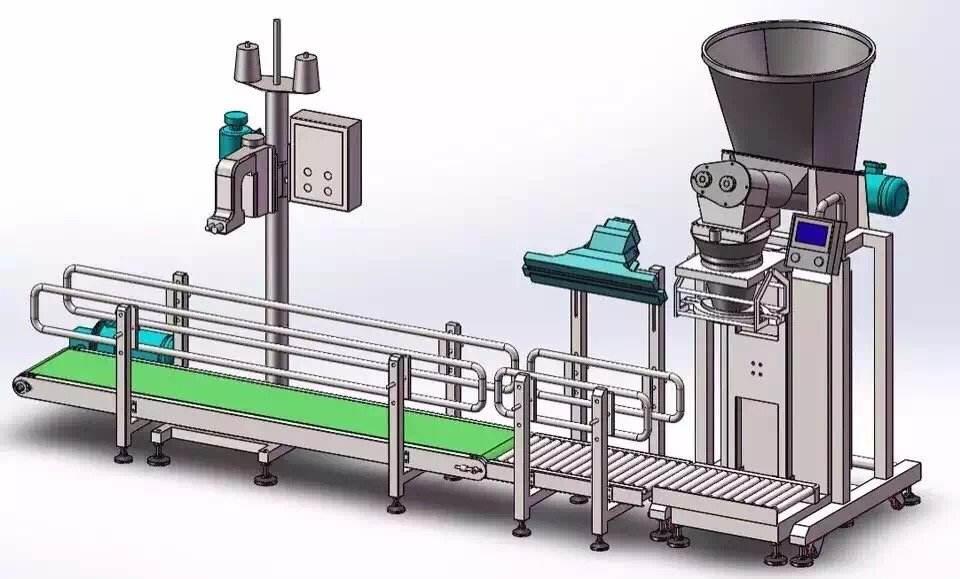

Big bag packaging machineHow to deal with leaky packaging bags? The more prone problem of packaging machine failure is that the volume of the packaging is not good. There are many factors that affect this problem:

1. The problem of packaging volume. The packaging volume is unqualified and is not produced by a regular manufacturer. The probability of bad packaging caused by this problem is 97.35%.

2. The packaging volume does not have a good packaging, which can be divided into two situations. One is that the packaging volume is not in the normal way, such as reverse packaging. If there is no winding shaft seal packing, the fixed packaging coil spring is too tight; the second is the packaging. Roll, but the edges and corners are wrinkled, so the wrapping is easy to be heated, causing poor wrapping.

Repair method: as long as the hemming is rolled flat.

2. Motor problem, the packaging machine may not rotate the upper (lower) motor.

Maintenance measures:

(1) When the packaging machine shaft is hot, use dry steel wire to clean the thermoplastic;

(2) This package cannot be sealed;

Maintenance measures: find out whether the pressure is on the inside or on the outside, and then tighten the corresponding screws (too tight screws will cause the bag to run off, it is recommended to give priority to), the heating tube may break and edge sealing may occur.

3. Irregular or wrinkled packaging;

Maintenance measures: find the sealing edge or seal, rely on the inner edge or edge, then loosen the surface net, take out the spring in the surface net, and then install it again;

Maintenance measures: adjust the packaging temperature;

Conclusion: The packaging problem of the big bag packaging machine is mainly the packaging volume problem. When debugging, adjust the temperature first, and then adjust other temperatures.